- Controls up to 4 heated zones

- Uses a single wire to resistively heat the fast GC column and sense the temperature

- Programmable 8-state temperature profile for each channel

- Maximum programmable ramp rate of 2000°C/min*

- Compatible with any GC or analyzer

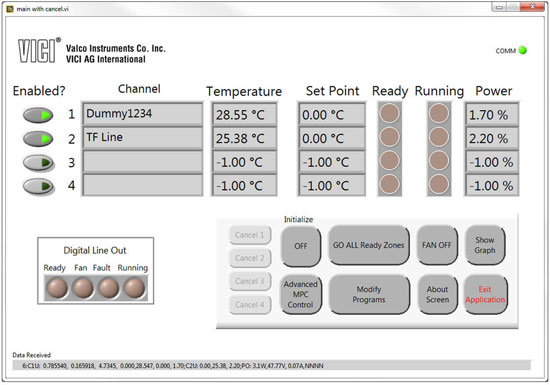

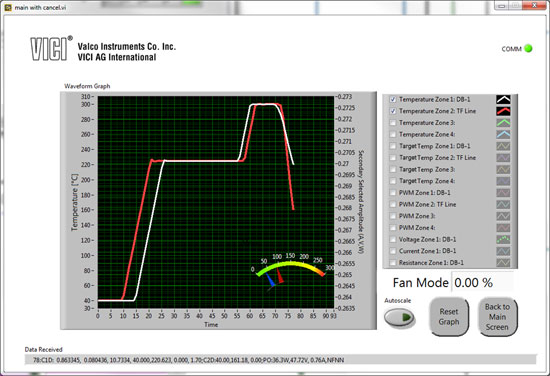

- User-friendly Windows-based software

- OEM and end user versions available

* Actual maximum ramp rate is dependent on the size of the column.

The FTP-200 (Fast Temperature Programmer) is a highly-configurable temperature controller with as many as four channels that can be programmed to ramp independently or simultaneously. The zones use a temperature-predictive algorithm and thermocouple or RTD input for precise control of multiple fast GC columns or related transfer lines, injector, etc.

The primary channel, specifically designed for precision temperature programming of low mass nickel-wire-wrapped fast GC columns, utilizes the nickel as both the heating element and the temperature sensor. This reduces the mass of the column, reduces the lag time between target temperature and actual temperature, and enables the use of a safe, low voltage to heat the column. A small fan can be used to cool the column to the starting temperature. (Check out our column/fan modules, designed for easy implementation with the FTP-200.)

The Windows-based control program (screen captures below) facilitates simple creation of temperature profiles with up to eight states for each channel. Multiple data parameters can be graphed, with data logged and analyzed. For users who prefer basic operation with raw data, control via a set of serial commands is accomplished via a terminal emulation or communication software running on a PC-compatible computer.

Product Numbers

The FTP-200 allows multiple configurations. The simplest version has only the main channel; the maximum is four. Beyond that, it can be ordered with or without an enclosure, and with or without a power supply. If it has a power supply, does it get a US power cord, a European power cord, or no power cord at all? There is also a choice of temperature-sensing options. The following link explains how the part numbers are formed. <Part number guide>

Specifications

| Parameter | Minimum | Maximum | Units | Notes |

|---|---|---|---|---|

|

Controller input voltage |

44 (48 nominal) |

55 | V | |

|

Controller input current |

0.1 | 10 | A(DC) |

Max current with power supply is 6.45A |

|

Operating temperature |

0 | 40 | °C | |

|

Storage temperature |

-25 | 70 | °C | |

| Humidity | 0 | 95 | % | Non-condensing |

|

Output voltage |

0 | 46 | V | |

|

Peak output current |

0 | 6.25 | A | |

|

Continuous current/channel |

0 | 5 | A | |

|

Programmable ramp rate |

1 | 2000 | °C/min | |

|

Heating power |

500 | W |

All zones power supply max 310W |

|

|

Digital outputs impedance |

60 | 150 | Ω |

Contact closure |

|

Digital output max voltage |

5 | 24 | V | |

|

Digital output current |

10 | 200 | mA | |

|

Digital input |

4.9K Ω pull-up |

|||

|

RTD temperature |

0 | 450 | °C | |

|

Thermocouple temperature |

0 | 400 | °C | |

|

Wire sensing resistance |

2 | 20 | Ω | |

|

Input voltage |

90 | 264 | VAC | |

|

Input frequency |

47 | 63 | Hz | |

|

Input current |

5 | A |

At 115 VAC |

|

| 2.5 | A |

At 230 VAC |